Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Industrial Inkjet Printers for Reliable Manufacturing Marking & Coding

Modern industrial manufacturing needs clear, durable codes in order to maintain product traceability. These marks cover everything from batch numbers and barcodes to lot codes and branding. Industrial inkjet printing solutions provide the flexibility and precision industries need to keep lines moving. These printers deliver top-of-the-line industrial coding performance across all materials and production environments.

Metal

Plastic

Ceramic

Wood products

Rubber

Plastic containers

Metal containers

Paper bags

We’re here to provide you with more details.

Reach out today!

Date Coding for Industrial Manufacturing

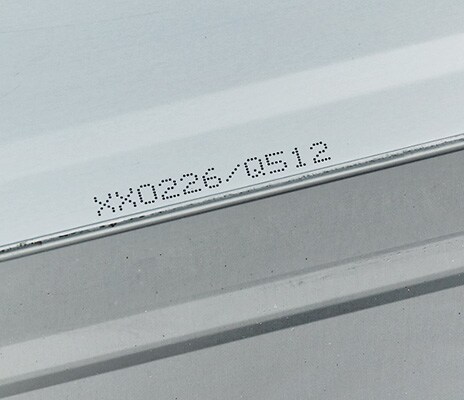

Construction & Building Materials

This industry requires durable products that adhere to strict safety standards. KEYENCE’s MK-G Series is IP55-rated. The head and controller can withstand dusty environments, ensuring traceability and compliance with regulatory requirements.

Click here to see "Coding on Construction and Building Materials"

Printing example

Installation example

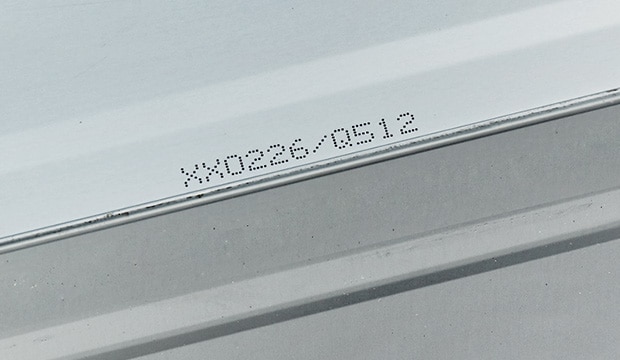

Automotive and Aerospace

Date coding for industrial manufacturing is important for traceability and compliance. KEYENCE’s MK-G Series provides high-speed and stable marking solutions for lot numbers, serial numbers, and barcodes, even in harsh environments.

Click here to see "Coding on Automotive and Aerospace Parts"

Printing example

Installation example

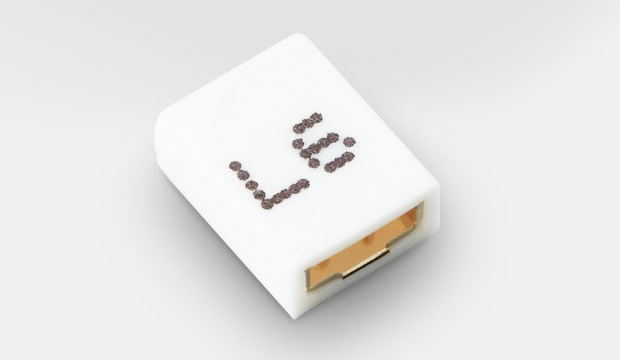

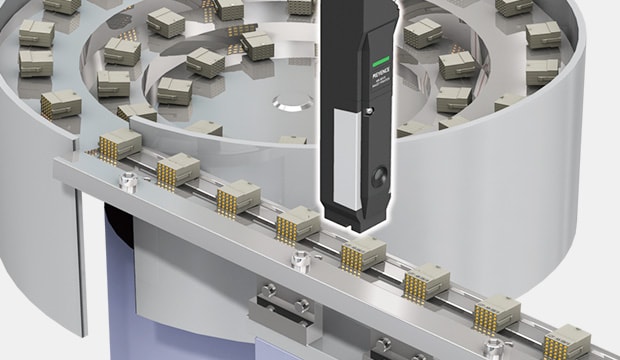

Electrical Components & Electronics

Electrical components & electronics require specific high-quality information to be displayed in small mark windows. KEYENCE CIJs integrate seamlessly into small applications, offering a micro nozzle that prints with extreme accuracy for semiconductor applications.

Click here to see "Coding on Electrical Components & Electronics Industry"

Printing example

Installation example

Wire and Cable

Printing example

Wires and cables require a variety of markings, including name, size, and rating information to meet safety regulations. KEYENCE CIJs handle continuous production without frequent maintenance, resulting in reduced downtime and costs.

Click here to see "Coding for the Wire and Cable Industry"

Piping & Extruded Materials

Adhesion and print quality is critical for marks on piping and extruded materials. KEYENCE’s MK-G Series monitors breakpoints and dot condition 10 times per second to ensure high-quality codes, eliminating rework and scrap.

Click here to see "Coding on Piping and Extruded Materials"

Printing example

Installation example

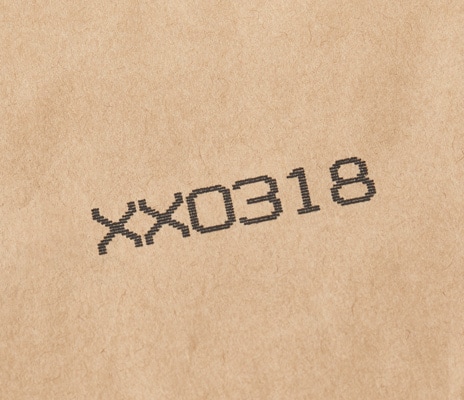

Chemicals

Chemical manufacturing relies on CIJs for batch, shift, and industrial date coding. KEYENCE CIJs provide reliable coding in harsh environments, including high-temperatures, dusty and wet conditions. KEYENCE CIJs are designed to withstand these challenging conditions due to their IP55 rating an drop protection.

Click here to see "Coding on Chemical Packaging"

Printing example

Installation example

Metal

Coding on metal parts is vital to ensure traceability and quality control. The MK-G Series has a state-of-the-art automatic ink particle sensing system, ensuring the printer can maintain the best possible ink conditions and provide stable and high-quality printing on metal materials.

Click here to see "Coding on Metal Materials"

Lumber and Wood

Coding on lumber & wood products is crucial for efficient tracking and delivery of products, helping to prevent mix-ups. However, it can be challenging due to uneven textures and moisture levels.

Click here to see "Coding on Lumber and Wood Products"

Extrusions

Extrusion efficiently produces uniform items like pipes and tubes, but coding on extrusions is challenging. Lubricating oils can cause smudging, and high temperatures may affect code clarity, complicating operations.

Click here to see "Coding on Extrusions"

Curious about our pricing?

Click here to find out more.

Benefits of Non-Contact Inkjet Marking in Industrial Manufacturing

Non-contact high-speed printing supports clear marks on any surface, like metals, plastics, films, and cartons, without affecting the surface. The ink stream stays stable as each drop lands, so characters remain sharp even when the product shape changes or the line moves quickly. Regardless of various textures (some parts being smooth and others coarse or bumpy), an inkjet printer for manufacturing handles both without adjustment.

How Inkjet Printers Improve Manufacturing Efficiency and Traceability

To put it simply, industrial coding systems strengthen operational efficiency. Automated printing of lot numbers, barcodes, and traceability data reduces manual labeling while keeping production data consistent across facilities. Connected controllers and web-based interfaces give operators full visibility into ink usage, temperature, and line performance. These industrial inkjet printing solutions help maintain stable throughput and high first-pass yield, reducing human error and downtime, and their durable inks withstand heat, moisture, and abrasion.

Reliable Coding Systems for Complex Industrial Applications

Across industries, from automotive components to electronic parts, production lines rely on stable performance from every coding unit. Industrial continuous inkjet (CIJ) printing systems achieve continuous operation through automated cleaning cycles, closed ink circulation, and real-time nozzle monitoring with a sealed design that prevents contamination from dust or humidity while keeping print consistency high. Whether applying micro text to a circuit board or large lot codes to metal housings, each CIJ industrial inkjet printing machine delivers the precision and speed required for harsh and demanding environments.

Discover more about this product.

Click here to book your demo.

Why Choose KEYENCE Industrial Inkjet Printers for Your Production Line

KEYENCE builds industrial inkjet printing solutions, like the MG-K Series, that stay productive under real manufacturing pressures. Start-up and shutdown routines run on their own, so ink remains stable and ready when the line changes over. The print head is compact and protected by a rugged frame that holds up in dusty areas, on fast conveyors, or near equipment that generates vibration. Control settings adjust on their own as conditions shift, and the interface keeps day-to-day work simple for any team member. With these systems in place, inkjet marking stays steady across long shifts without constant attention.

Key Features of KEYENCE Industrial Inkjet Printers for Manufacturing

Each printer is engineered for performance under real production conditions. Multiple ink formulations support different production needs, whether the job calls for dye-based ink or pigmented blends. Sensors inside the system watch ink flow and drop formation, so the stream stays steady through long runs. The inks dry quickly, which helps marks stay readable on curved parts or products that move fast on the line. Resolution stays high as well, giving text and codes the clarity needed for product IDs or larger packaging marks. Connectivity options, including LAN and remote monitoring, allow teams to manage every printer from one console for complete process visibility.

Simplifying Production Line Integration with KEYENCE Inkjet Solutions

Integration flexibility keeps production upgrades simple, compact control units fit easily beside conveyors or robotic arms, and communication protocols connect directly to existing PLCs or factory networks. Data such as batch information or date codes can be transmitted automatically from central systems, eliminating setup time between product runs. The result is faster changeovers, consistent code placement, and real-time coordination with inspection or measurement systems. Each system is built to adapt to changing production needs without interrupting throughput.

Request a Demo and See the Difference in Your Production Line!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About CIJs for Industrial Manufacturing

What Are the Key Advantages of Using KEYENCE CIJs for Industrial Manufacturing?

The main advantages of CIJs for industrial manufacturing are high uptime, ease of use, durability, print quality, and reduction of running costs and human interaction (less user error).

What Features Differentiate KEYENCE’s Continuous Inkjet Printers for Industrial Manufacturing?

Continuous inkjet printers offer a wide range of inks, backup power modules, a MIL standard-compliant/impact-resistant structure, Smart Startup and event recording functions.

What Impact Do Continuous Inkjet Printers Have on Production Efficiency and Downtime in Industrial Manufacturing?

Due to IP and MIL drop-rated print heads,KEYENCE CIJs perform robustly in dusty or wet conditions and have greater productivity and performance compared to other technologies.

How Do Continuous Inkjet Printers Simplify Marking/Date Coding for the Industrial Manufacturing Industry?

Industrial inkjet printers provide non-contact printing on most substrates with high marking permanence in harsh environments.

What Are the Primary Considerations When Selecting CIJs for Industrial Manufacturing?

CIJ dimensions and ease of integration into the production line are important considerations. Throughput or marking speed is also important, and CIJ printers should also be easy to maintain and clean.

How Do Continuous Inkjet Printers Handle the Challenges of Printing Date Codes on Uneven or Curved Surfaces Commonly Found in Industrial Manufacturing?

The CIJ printer's nozzle can print on uneven or curved surfaces from a distance without touching them, preventing damage to delicate or irregularly shaped objects.

How Do Continuous Inkjet Printers Ensure Compliance with FDA and Other Regulatory Standards for Date Coding on Food Across Industrial Manufacturing?

Continuous Inkjet printers reliably print high-quality and accurate date and lot codes to ensure compliance with FDA and other regulatory standards.

How Does Non-Contact Inkjet Printing Work in Manufacturing?

A continuous flow of ink droplets is deflected toward the target surface, creating clear text or codes without touching the product.

What Makes KEYENCE Printers Reliable for Industrial Applications?

Automated cleaning, stable ink circulation, and rugged housings allow consistent marking in dusty, humid, or high-speed conditions.

Can These Printers Integrate with Existing Equipment?

Yes, network and PLC connectivity allow direct integration with production control systems, enabling real-time data sharing and remote management.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper