Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Automotive & Aerospace Parts Coding

Modern automotive and aerospace production depends on reliable part identification at every stage of manufacturing. Components move through machining, welding, assembly, and inspection at a continuous pace. A continuous inkjet (CIJ) marking printer for automotive and aerospace parts gives teams clear, consistent data without slowing the line. Each code connects the part to upstream material records, downstream testing results, and long-term service tracking across complex supply chains.

Achieving Precision Marking for Automotive & Aerospace Manufacturing

Both industries use a wide mix of machined metals, cast housings, composite structures, molded plastics, and rubber components. Surfaces vary in finish, shape, and flexibility, so operators need markings that stay readable under changing conditions. A modern inkjet marking printer for automotive and aerospace parts applies characters without contact, which protects the substrate and maintains print stability even when texture or curvature shifts. This supports batch-level and part-level tracking throughout fast, uninterrupted production.

We’re here to provide you with more details.

Reach out today!

Date Coding and Marking on Automotive and Aerospace Parts

Metal Products

In manufacturing, strict regulations ensure metal product safety and quality, often requiring date coding. Industrial inkjet printers guarantee traceability with accurate, fast coding, eliminating errors and maintaining high-quality codes even in harsh environments.

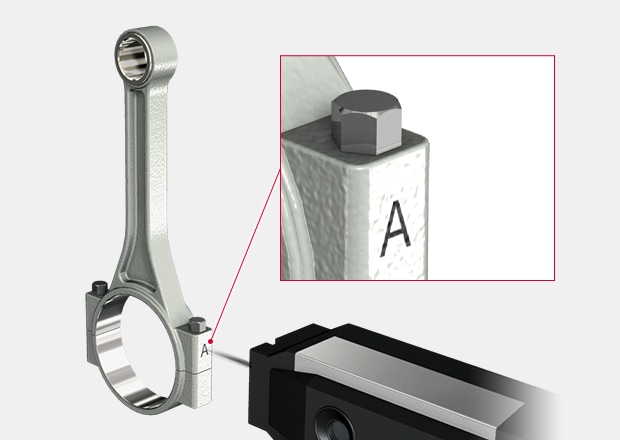

Marking aluminum wheels

Marking the rank on a connecting rod

Piston

The rank for assembly in a later process is marked as a character string and 2D code.

Muffler

The muffler size and specifications vary depending on the vehicle in which the muffler will be installed, so marking is performed for identification.

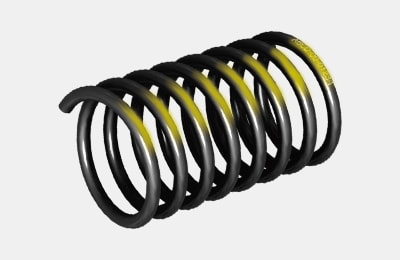

Spring

An inkjet printer can be used to apply color to springs. This can be used to identify different products that have the same shape.

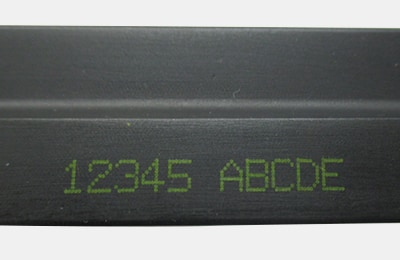

Extrusion-Molded Products

Extrusion-molded products need precise marking (lot numbers/serial numbers/barcodes) to avoid recalls and compliance issues. KEYENCE CIJ printers ensure high-quality marks by monitoring break points and dot conditions, guaranteeing adhesion and print quality.

Timing belt

The inkjet method is effective due to the concerns regarding damaging rubber timing belts.

Tires

Since laser markers are not effective on all types of rubber, using an inkjet printer is an effective method of marking tires.

Wiper blade

Marking is performed on the rubber component of the wiper blades. The manufacturing speed is fast enough during extrusion molding that other marking methods cannot keep up. An inkjet printer would be the most effective means of marking this type of part.

Parts

Parts differ in materials, shapes, and finishes, making accurate marking challenging. Traditional methods lack durability and precision. KEYENCE CIJs integrate seamlessly into production lines, ensuring legible and compliant coding on automotive and aerospace parts.

Side mirror

Marking is performed on the back surfaces of the side view mirrors. Conventionally, this marking was performed by hand, but this process can be automated by using an inkjet printer, which can lead to increased production.

Switches

These switches are installed in the vehicle's dashboard. Marking with an inkjet printer can be used to prevent problems such as friction after assembly.

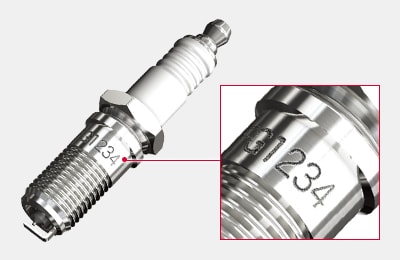

Spark plug

Marking to identify spark plugs for use in different vehicles is performed on the cylindrical surface.

Curious about our pricing?

Click here to find out more.

Addressing Key Challenges in Automotive and Aerospace Marking

Components like engines, brakes, and electronics are labeled with key data such as manufacturing dates and serial numbers, supporting quality control, maintenance, and recalls. Manufacturers face many challenges in ensuring accurate date coding, including compliance and maintaining efficiency on high-speed production lines:

- High Regulation: The automotive and aerospace industries are tightly regulated due to potential risks. Minor automotive parts date coding errors can cause recalls, delays, or safety hazards.

- Harsh Production Environments: Production lines operate at high speeds and extreme temperatures, challenging traditional coding methods.

- High Production Speeds and Volumes: The automotive and aerospace industries struggle with coding due to high quotas, limited staff, and maintenance needs.

- Complex Marking: Parts differ in materials, shapes, and finishes, making accurate marking challenging. Traditional methods lack durability and precision.

The Importance of Date Coding and Marking on Automotive and Aerospace Parts

Date coding on automotive and aerospace parts is essential for:

- Ensuring Traceability in Metal Products: In manufacturing, strict regulations ensure metal product safety and quality, often requiring date coding.

- Reliable Marking for Extrusion-Molded Products: Extrusion-molded products, such as rubber hosing, tubing, trims, and tires, need precise marking (lot numbers/serial numbers/barcodes) to avoid recalls and compliance issues. Rubber hosing and tubing are essential components in applications like automotive systems and industrial machinery. Rubber trims and tires are also mostly found in the automotive and aerospace industries, offering the functionality and durability necessary for efficient operations.

- High-Performance Coding for Paper, Glass, and Ceramic Components: Automotive date coding on paper, glass, and ceramic products comes with unique challenges. Paper requires smudge-resistant solutions to maintain legibility, while glass needs adhesion methods to prevent smearing. Ceramics, on the other hand, need precise coding applications to avoid damage or cracks.

- Precision Coding for Plastic Parts and Components: Plastic parts and components are essential in the automotive and aerospace industries for their durability, cost-effectiveness, and design flexibility. Used in components like dashboards, door panels, and sensors, accurate date coding ensures traceability and helps streamline high-volume production while minimizing errors.

Why CIJs Are the Best Choice for Marking Automotive and Aerospace Parts and Components

The KEYENCE MK-G Series provides precision, durability, and high-quality date coding for automotive and aerospace components, ensuring compliance with strict industry standards. Its low maintenance requirements, seamless integration into production lines, and robust performance help manufacturers streamline operations, reduce downtime, boost efficiencies, and minimize errors in high-demand environments.

Industrial inkjet printers guarantee traceability with accurate, fast date coding on automotive and aerospace parts while meeting other demands, including:

- Precise, Non-Contact Marking: Ensures clear and legible codes on various materials, including metal, plastic, rubber, and ceramics, without causing damage.

- Durability in Harsh Environments: With a MIL standard drop-rating and IP55-rated print head, the MK-G Series thrives in dusty, wet, and extreme conditions, ensuring consistent print quality.

- Self-Maintaining Technology: The MK-G Series comes with smart docks and self-diagnostics, reducing manual intervention and boosting productivity.

- Reliable, Scannable Codes: Continuous monitoring of breakpoints and dot conditions guarantees adhesion and legibility, even under variable environments and production speeds.

- User-Friendly Design: The intuitive interface and low maintenance requirements make it easy to operate, allowing more skilled technicians to focus on more complex tasks without constant troubleshooting.

How KEYENCE Inkjet Printers Optimize Aerospace Part Production

Aerospace workflows rely on full documentation from raw material through installation. An inkjet coding system for aerospace manufacturing places consistent identifiers on structural components, brackets, and engine parts as they move through machining, surface treatment, and inspection.

CIJ technology marks recessed, curved, or hard-to-reach surfaces at speed, reducing manual handling and keeping codes readable after exposure to heat, fluids, vibration, or post-processing. Stable drop formation and precise character placement help aerospace teams maintain clean links between printed IDs, build records, and inspection logs.

Discover more about this product.

Click here to book your demo.

Key Features of KEYENCE Marking Systems for Automotive Parts

Automotive lines move quickly, and the mix of materials on the line can change throughout a shift. A CIJ system adapts to those changes because its drop control remains stable as surfaces vary. Marks stay clean on machined parts when components are moving through automated handling. Rubber parts, including items like timing belts or wiper elements, benefit from non-contact printing that avoids distortion and eliminates the risk of heat-related damage.

Tracking and Traceability in Automotive and Aerospace Manufacturing

Tracking and traceability shape daily work in both industries. Parts are marked the moment they enter production, and those codes follow each component through machining, coating, testing, and final assembly. Each printed ID ties that step to batch data and inspection records. An inkjet marking printer for automotive and aerospace parts gives teams clear, readable identifiers that hold up through all of the changes it experiences throughout the supply chain. Forward and backward traceability both depend on codes that stay intact from the first process to the last.

The Role of Inkjet Printers in Aerospace & Automotive Compliance

Regulated industries depend on clear part IDs from the first cut of material to the final inspection. In aerospace shops, a code links each part to the lot it came from and the steps it passed through. Automotive plants follow a similar approach, but at a faster pace, with parts moving through automated tools almost nonstop. A stable inkjet coding system built for aerospace and automotive production delivers reliable output even as materials change across the line. It keeps print quality consistent from part to part, regardless of how the surface behaves during manufacturing. Clear text, 2D codes, and lot IDs support compliance audits, build history reviews, and service-life tracking across both industries.

Reliable Inkjet Solutions for Harsh Manufacturing Environments

Environmental variation is part of daily operation in both industries. Machining cells produce coolant mist, welding areas generate heat and particulates, and assembly stations often run around the clock. A production-ready CIJ system maintains drop control and readability in these conditions, giving teams consistent metal parts marking and reliable output on other substrates. Print heads built for industrial conditions provide steady performance through vibration, temperature changes, and airborne contaminants, allowing operators to keep lines moving during long production runs.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About Date Coding in the Automotive and Aerospace Parts

What Are the Benefits of Using KEYENCE's CIJ in the Automotive Industry?

The benefits include compliance with regulations through accurate date coding on automotive and aerospace parts for traceability and product safety, and minimal maintenance requirements.

How Does the MK-G Series Address the Challenges of Harsh Environmental Conditions Typical in the Automotive Industry?

The MK-G Series print head and touch screen meet MIL drop standards. The MK-G print head, controller body, and touch screen also have an IP55 rating, making them ideal for harsh automotive conditions. These durable and reliable components ensure smooth date coding on automotive and aerospace parts even in demanding environments.

How Does the MK-G Series Support User-Friendly Coding and Marking Solutions for the Automotive Industry?

The MK-G Series offers user-friendly date coding on automotive and aerospace parts, featuring minimal human interaction, seamless production line integration, self-diagnostics, and automatic maintenance.

How Does the Continuous Inkjet Printer Enhance Efficiency in Automotive and Aerospace Coding and Marking Processes?

There are several key benefits: improved throughput or marking speed, ease of maintenance and cleaning, and accuracy and clarity of date codes.

How Does the Continuous Inkjet Printer Ensure Quality Date Coding on Automotive and Aerospace Parts?

KEYENCE CIJs feature a built-in monitoring system that checks for break points or dot conditions up to 10 times per second. It offers non-contact printing and easily integrates with other KEYENCE inspection equipment.

What Are the Most Challenging Materials for Inkjet Printers in Automotive and Aerospace?

Rubber components, textured plastics, and coated parts are the toughest. A stable CIJ system keeps code readable across all of them.

How Do KEYENCE Inkjet Printers Improve Traceability in the Automotive Industry?

They deliver consistent identifiers that link each part to batch data, process steps, and inspection results, supporting clear visibility across the line.

Can KEYENCE Inkjet Printers Mark High-Temperature or Metal Parts?

Yes. CIJ printing produces sharp, durable codes on metals and components exposed to heat, fluids, and vibration throughout production.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper

![Process-specific Marking Applications [Food/Pharmaceutical Industry]](/img/asset/AS_133442_L.jpg)