Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Reduce Downtime and Operating Cost with Less Cleaning and Maintenance

Key Takeaways

- CC-1000 Series’ 360 DPI printhead with more than 1,000 nozzles provides nozzle redundancy to maintain print quality and reduce downtime.

- Longer throw distance prevents ink splashback, cutting manual wipe-downs and lowering cleaning frequency.

- CC Cleaner enables weekly maintenance instead of multiple shifts per day, reducing labor and fluid waste.

- Reduced cleaning raises MTBF, lowers MTTR, and improves OEE—translating to measurable operating-cost savings.

Industrial printers keep lines running, but constant cleaning slows everything down. Clogs, viscosity problems, and manual wipe downs drain time and money, raising labor and repair costs while output falls.

The answer is a smarter design. Advanced printhead technology and automated printhead cleaning systems cut routine maintenance, helping facilities reduce downtime and unlock real operational savings.

The Challenge: Frequent Cleaning and Maintenance in Industrial Printers

Downtime is one of the costliest problems on the plant floor. In many cases, a single stoppage can drain thousands of dollars an hour. With printers, the damage isn’t limited to idle machines, as wasted ink, spoiled batches, and operators pulled away from production all add to the loss.

Printhead clogs drive most of these interruptions. Dried ink and debris block nozzles, forcing constant flushing. Continuous inkjet systems often need intervention when viscosity shifts, while thermal and piezo printers deal with overheating or broken text when drops fail to form correctly. Even the environment works against them: dust, heat, or humidity accelerate buildup and foul the system faster.

Stopping to clean a printhead turns what should be routine maintenance into a chain reaction of delays. Planned breaks extend into unscheduled downtime, deadlines slip, and costs climb as labor and materials are consumed.

We’re here to provide you with more details.

Reach out today!

Manual Cleaning Burdens and Associated Costs

Manual cleaning may seem routine, but its hidden costs add up quickly. Labor is the largest factor, accounting for up to 90% of cleaning-related expenses in many facilities. Operators must purge, wipe, and reset printheads, a process that interrupts their ability to focus on higher-value tasks. When clogs or splashback require repeated cleanings, the cumulative hours stack into days of lost production each year.

Consumables also contribute to the expense. Manual methods often waste ink and solvents, either through repeated purges or discarded materials following poor-quality prints. Over time, the cost of this waste can rival the price of replacement parts. Mechanical wear from repeated handling further shortens the lifespan of delicate components, raising long-term maintenance costs.

There is also the matter of risk. Each cleaning cycle creates an opportunity for error. Improper handling, misaligned cartridges, or incomplete purges can all extend downtime rather than reduce it. In fast-paced environments, operators often face pressure to get machines running again quickly, which increases the likelihood of mistakes. This reactive cycle drains both productivity and morale.

Infrequent or Improper Maintenance

Putting off maintenance often feels like saving time, but it usually costs more later. A skipped cleaning lets ink harden in the nozzles. Ignored leaks spread and strain other parts of the system. Minor wear that could have been caught early turns into a major repair. What starts as a few missed tasks can end with a breakdown that’s harder (and far more expensive) to fix.

Facilities that operate on a “run to failure” approach experience more catastrophic downtime events. A breakdown like this can take hours or even days to clear, pulling in emergency parts and outside help at premium cost. Add overtime to cover the gap, and what looked like saved time quickly becomes a spike in operating expense.

A strong preventive maintenance program addresses these issues, but it is only effective when compliance is high. Delayed or incomplete tasks undermine the entire strategy, leaving facilities vulnerable to the same cycle of failures. What is needed is technology that reduces the demand for maintenance in the first place.

Curious about our pricing?

Click here to find out more.

The CC-1000 Series Advantages: High-Resolution Printhead with Minimal Maintenance

The CC-1000 Series was built to reduce downtime in industrial printers. Its 360 DPI printhead uses more than 1,000 nozzles, creating sharp codes with built-in redundancy. Even if a few nozzles clog, quality remains stable without forcing an immediate stop for cleaning.

Its long throw distance is another advantage. Printing from farther away eliminates ink splashback, a common cause of repeated wipe downs in older systems. With splashback removed, operators spend less time on cleaning and more time on production.

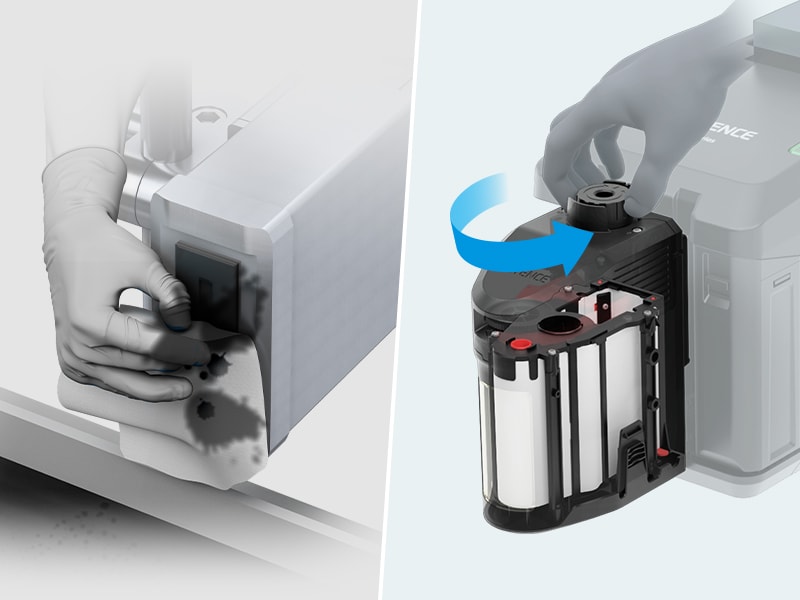

When maintenance is required, the CC Cleaner turns it into a quick weekly step rather than a daily disruption. That cuts labor, reduces fluid waste, and makes the process straightforward for any operator. Compared to systems that depend on a Micro Purging System and recycled ink, the CC-1000 Series lowers maintenance needs by design.

Comparing Maintenance Requirements: Micro Purging vs. High-Resolution Systems

Older printers often need several cleanings a shift just to keep codes legible. Each stop eats up labor and adds the chance for mistakes. Operators spend more time wiping nozzles than running the line.

The Micro Purging System cuts down on full flushes, but it comes with trade-offs. The system reuses dirty ink and leans on filters that need frequent replacement. The CC-1000 Series avoids that cycle altogether by purging dirty ink and removing the need for replacing filters to ensure the unit runs consistently and smoothly. Its longer throw distance stops splashback before it starts, and the dense nozzle array holds print quality even if a few ports clog. The payoff is practical: operators clean once a week with the CC Cleaner instead of pausing the line several times a shift.

Real-World Impact: Cost Savings and Increased Uptime

The financial impact of reducing downtime is straightforward. Every avoided cleaning cycle means fewer labor hours, less wasted ink, and lower repair frequency. Over time, those savings compound into significant operational savings.

Consider the true cost of downtime: labor for technicians and operators, the price of replacement parts, wasted materials from interrupted jobs, and lost production capacity. By cutting even a fraction of cleaning-related stoppages, facilities recapture hours of productive time each week. This time translates directly into higher throughput, fewer missed deadlines, and improved customer satisfaction.

Lower maintenance frequency also extends the lifespan of critical equipment. Just as better cleaning chemistry prolongs the life of facility machines, advanced printhead technology reduces wear and delays the need for costly replacements. The capital freed by extending asset life can then be reinvested into growth rather than repairs.

Quantifiable Benefits: Reduced Downtime and Maintenance Costs

The difference shows up quickly once cleaning cycles drop. Plants that move from daily manual wipe downs to a simple weekly routine recover hours of production time each month. Automated purges replace long flushes, trimming both the length and the number of stoppages.

The metrics back it up. Mean time between failures (MTBF) rises because clogs are less frequent. Mean time to repair/recover (MTTR) falls because cleaning is faster and simpler. Overall equipment effectiveness (OEE) improves as availability and performance stop slipping away due to constant maintenance.

Even small gains add up. Saving just an hour of downtime a week can mean thousands in recovered output each year. On a large line running around the clock, that figure scales into the millions.

Reduce operational costs and improve your printing efficiency with the CC-1000 Series. Contact us today to get started!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

What Are the Benefits of Automated Printhead Cleaning Systems Compared to Manual Methods?

Automated systems provide consistent cleaning with less waste, cutting labor costs and downtime while maintaining print quality.

How Does Modern Printhead Technology Contribute to Operational Savings?

By reducing maintenance frequency, using less consumable fluid, and extending component lifespan, advanced printhead designs lower the total cost of ownership.

Which Industries Gain the Most From Reduced Downtime in Industrial Printers?

High-volume sectors such as food and beverage, pharmaceuticals, automotive, electronics, and logistics benefit most, as every minute of uptime directly affects output and profitability.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper