Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

CIJ for the Food and Beverage Packaging Industry

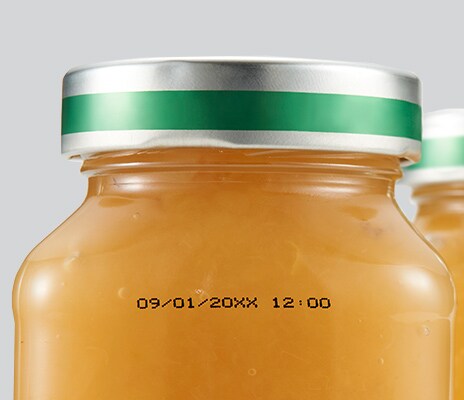

Food and beverage production runs nonstop, and every product that leaves the line carries vital data defining its safety, shelf life, and traceability. A beverage marking printer plays a crucial role in applying this information accurately and consistently. From lot numbers on bottles to barcodes on cartons, accurate marking ensures compliance and maintains steady production. Continuous inkjet (CIJ) technology delivers the speed and reliability needed for high-volume food packaging coding in fast, sanitary environments.

Why Marking Is Essential in the Food & Beverage Industry

Each printed date, batch, and code supports traceability and quality control across the supply chain. From the filler to the shelf, packages must carry data that stays visible and intact and consistent date coding on food and beverages to help teams determine freshness, manage rotation, and avoid waste. Retailers depend on those details to keep stock current, and shoppers rely on them for confidence in product quality. CIJ printers keep this information clear at production speed, reducing errors and downtime while helping brands maintain consistency and trust.

Packaging films

Cardboard boxes

Product bottles

Paper bags

Cartons

Liquor labels

Containers and caps

Cans

We’re here to provide you with more details.

Reach out today!

Date Coding for Food and Beverage Packaging

Dairy

Dairy products require date coding on food packaging for freshness and safety. KEYENCE CIJs for the food and beverage packaging industry increase uptime and easily integrate into packaging lines.

Click here to see "Coding on Dairy Packaging"

Printing example

Installation example

Packaged Foods

Packaged foods have strict regulations requiring lot and date coding on food packaging. KEYENCE CIJs print on glass, metal, and plastics (PET, PP, PE) with high speed and accuracy.

Click here to see "Coding on Packaged Foods Industry"

Beverages

Beverage producers must maintain high-speed production. KEYENCE CIJs maintain print quality at speeds over 1,200 cans/bottles p/min, even in challenging environments.

Click here to see "Coding for the Beverage Industry"

Printing example

Installation example

Baked Goods and Cereal

KEYENCE CIJs enable accurate printing on films, foils, wrappers, clamshells, cardboard, and plastics. The MK-G Series excels in date coding on curved surfaces like cans and bottles.

Click here to see "Coding on Baked Goods Packaging"

Candy and Confectionery

Candy and confections are packaged in materials like plastic and cardboard. KEYENCE’s MK-G Series inkjet printers quickly print high-quality date codes on various packaging materials.

Click here to see "Coding on Candy and Confectionery Packaging"

Egg

Egg cartons need strict date coding on food packaging for FDA compliance. KEYENCE CIJs offer complex code printing and automated cleaning, reducing contamination, downtime, and manual intervention.

Click here to see "Coding on Egg Cartons"

Fruits and Vegetables

Consumers prioritize food safety and origin. KEYENCE’s CIJs adapt to temperature changes and automatically wash down the inside of the print head limiting exposure to chemicals to maintain quality, and safety while reducing downtime.

Click here to see "Coding on Fruit and Vegetable Packaging"

Meat and Poultry

Clear date coding on food packaging is needed for safety and traceability. MK-G Series printers provide remote monitoring and built-in diagnostics, cutting down maintenance staff needs and boosting efficiency.

Click here to see "Coding on Meat and Poultry Packaging"

Pet Food and Animal Feed

Coding solutions are required for retort pouches and chub packs. KEYENCE CIJs for the food and beverage packaging industry boost throughput and reduce waste on curved or flexible packaging.

Click here to see "Coding on Pet Food and Animal Feed Packaging"

Snacks

Accurate expiration dates ensure consumer trust, product quality, and freshness. KEYENCE's CIJ printers offer high-speed, quality printing for snack packaging, supporting 24/7 production demands without compromising quality.

Click here to see "Printing and Coding on Snack Packaging"

Curious about our pricing?

Click here to find out more.

How KEYENCE CIJ Printers Revolutionize Food & Beverage Marking

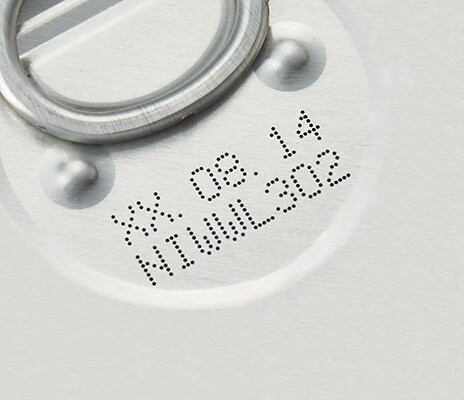

The KEYENCE MK-G Series sets a new benchmark for beverage marking printers. It automates cleaning, ink circulation, and error recovery to minimize operator intervention. Smart Startup and Smart Shutdown prepare and rinse the printhead automatically, limiting solvent use and extending uptime, while the IP55-rated housing handles daily wash-downs and humidity, and dual-circulation ink control maintains pigment balance for sharp, high-contrast codes on bottles, films, and cartons.

The printer manages its own ink mix, checking viscosity and temperature in real time to hold line quality. The MK-G1000 offers MEK-free, strong adhesive, and pigmented inks, like yellow, for different applications common in food and beverage packaging. When cleaning is needed, the MK Dock runs an enclosed rinse that’s finished before the next startup.

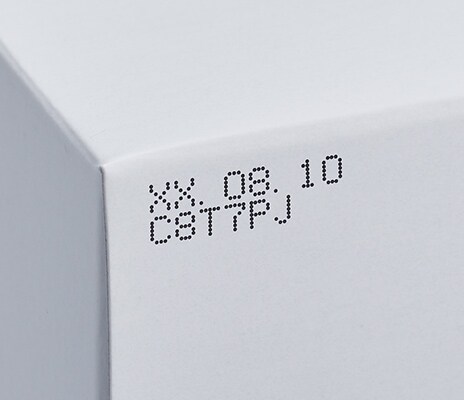

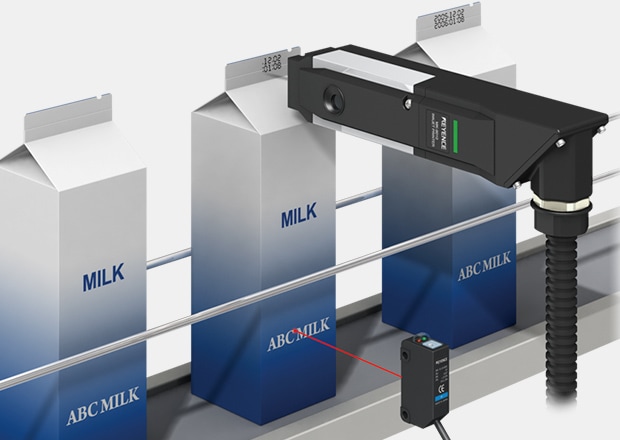

For secondary packaging, the KEYENCE CC-1000 Series provides 360-DPI resolution and a 0.6-inch throw distance that prevents nozzle contact and splashback. Its integrated inspection camera verifies every print, maintaining barcode accuracy on shipping cases without slowing production.

Common Marking Needs in Food & Beverage Production

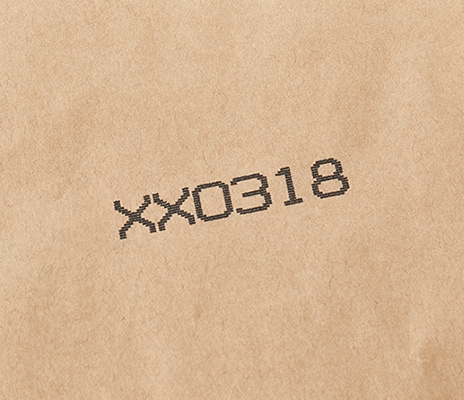

Food and beverage operations use a wide range of materials, including glass bottles, PET containers, aluminum cans, cartons, pouches, and flexible films. Beverage bottle printing often involves condensation and curved surfaces; food trays may require quick-dry inks that resist smudging during sealing. CIJ printers adapt to each substrate with precise droplet control and steady print placement, maintaining legibility through high-speed runs and frequent changeovers.

Across all packaging types, traceability remains constant. CIJ systems apply barcodes, lot identifiers, and expiration dates that hold up under refrigeration, moisture, and transport. The CC-1000 Series extends these capabilities to outer cases, creating a complete identification system from product to pallet and simplifying warehouse management.

Discover more about this product.

Click here to book your demo.

KEYENCE Benefits for Food & Beverage Companies

Uptime drives productivity, and the MK-G Series helps achieve it with automatic cleaning, guided part replacement, and predictive alerts that keep maintenance short and scheduled. The CC-1000 Series adapts to line speed and vibration, maintaining print clarity across shifts. With cartridge-based inks, long-life parts, and one-touch servicing, both the CC-1000 Series and MK-G Series cut waste and costs while delivering dependable industrial coding for food operations.

Find the Right KEYENCE Printer for Your Food & Beverage Marking Needs

KEYENCE covers every stage of packaging, from bottles to shipping cases. The MK-G Series manages fine CIJ printing on primary packages; the CC-1000 Series covers outer cartons with 360-DPI barcodes and text. They link easily into existing conveyors and vision systems. Together, they give plants one connected approach to food and beverage coding.

Contact KEYENCE today to learn how the MK-G Series and CC-1000 Series can advance your food packaging coding and beverage bottle printing performance.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

Can KEYENCE Printers Print on Both Plastic and Glass Packaging in Food and Beverage Applications?

The MK-G Series, a versatile beverage marking printer, prints clean, durable codes on glass, PET, aluminum, and film, ensuring legibility even under condensation and temperature changes.

What Makes KEYENCE CIJ Printers Ideal for Food and Beverage Production Lines?

CIJ printers operate at full speed with automatic cleaning, stable ink control, and hands-free maintenance. Built-in monitoring keeps print quality consistent even during extended runs.

How Can KEYENCE Maintain Compliance with Food Labeling Regulations?

By producing clear, traceable data such as lot numbers and expiration dates that remain readable through handling and storage, supporting complete product accountability.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper

![Process-specific Marking Applications [Food/Pharmaceutical Industry]](/img/asset/AS_133442_L.jpg)